IR Weld Bolt

Weld bolt with Increased Reliability of weld strength

IR Weld Bolt

Weld bolt with Increased Reliability of weld strength

- Advantages

- Unique shaft design reduces split current flows and enable to achieve more reliable weld strength.

- What is IR?

- Weld bolt with Increased Reliability of welding strength

- Industries

- Transportation, Automotive, etc.

- Applications

- Locations with inconsistent weld strength due in part to split flows

- Benefits

- Improves reliability of weld strength

- Size

- M6~M10

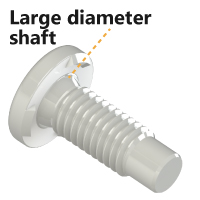

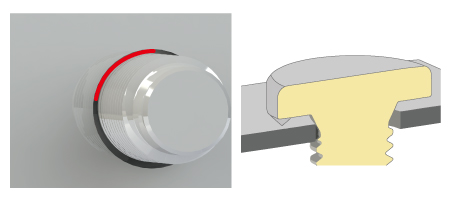

Conventional Products

<Issues>

Large diameter shaft for center-positioning but makes continuous contacts with mating hole arch and causes split flows.

Large diameter shaft makes contact with mating part. Continuous circular contact creates split flows and causes inconsistent dissolve condition.

- Reliability

- 90(Probability of satisfying applicable weld strength (Pushout torque))

- Cost Index

- 100

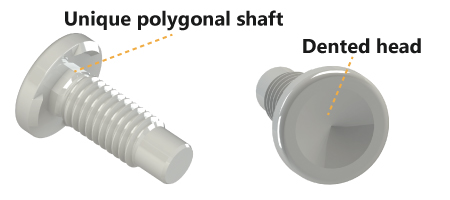

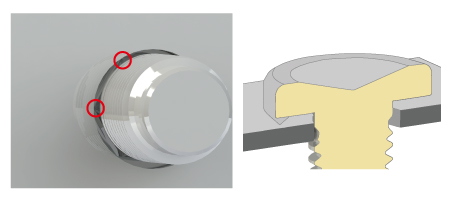

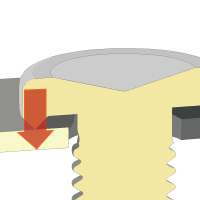

Developed Product

<Features and Benefits>

Shaft’s unique polygonal shape reduces split current flows.

Dented bolt head creates vertical current flows onto weld projections.

And the polygonal edge shape only allows local contacts with mating part and thus reduces split flows of current.

Dented head creates vertical current flows onto weld projections.

Tapered shoulder edge provides easy insertion against mating hole.

- Reliability

- 100

- Cost Index

- 70(Total cost that includes poor weld conditions and preventive measures.)