ICC Insert Nut

Insert nut with Improved plating feasibility and sliver clearance

ICC Insert Nut

Insert nut with Improved plating feasibility and sliver clearance

- Advantages

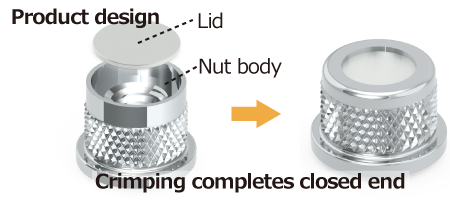

- Creating closed-end by crimping the lid eliminates common issues such as plating deposition

- What is ICC?

- IWATA BOLT Crimped Cap end

- Industries

- Transportation, Electronics, etc.

- Applications

- Injection molding assy that requires closed end insert nut

- Benefits

- Trimming overall length, improving corrosion resistance, quality and reliability

- Size

- M3~M8

CURRENT OPTIONS

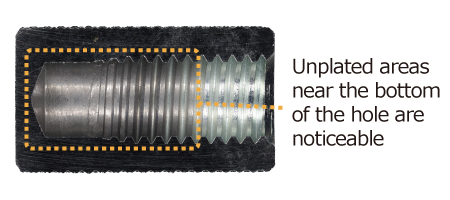

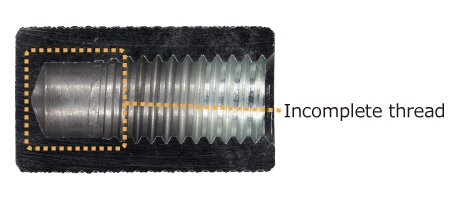

<DISADVANTAGES >

●Closed end prevents plating deposition

●Incomplete thread portion requires longer length

●Remaining plating solution creates drop marks and stains

●Slivers from drilling/tapping process remain inside nuts

●Closed end shape requires longer tapping process time and causes low productivity

- RELIABILITY

- 60(Reliability of ICC Insert Nut as 100)

- COST INDEX

- 100

ICC Insert Nut

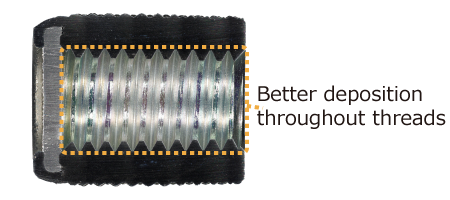

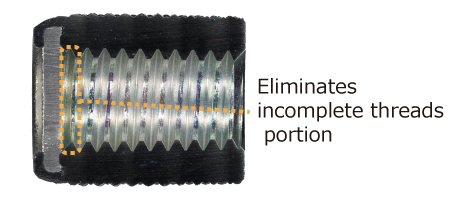

<Feature>

●Plating on open-end nuts enhances plating deposition throughout the threads and corrosion resistance improves as a result. Plating solution drains smoothly, leaving no marks or stains

●Shorter length with no incomplete thread

●Slivers effectively washed off through open-end hole

●Utilizing cold forging and bent tapping enhances productivity

- RELIABILITY

- 100

- COST INDEX

- 90(Cost of ordinary insert nut as 100)